When Sample Length Matters

Background:

Manufacturers of wire harnesses must ensure that crimped terminals remain securely attached to wires in their intended applications. To ensure performance, wire harness manufacturers typically subject samples to pull force testing to demonstrate compliance to minimum industry standards. In most cases, the sample consists of a wire with crimped terminal at one end. This type of sample is easily accommodated by common force testers. However, in this particular application, the customer needed to test a variety of sample lengths, some of which were very long. The samples needed to be secured at both ends.

How Mark-10 Helped:

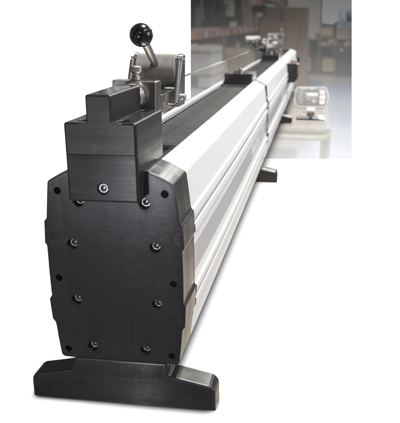

We worked with our distributor and the end user to develop a custom, turnkey solution based upon an extended length ESM1500LC motorized test stand. Our engineers added extruded column extensions and multiple mounting points for grips, thereby accommodating the full range of sample lengths.

Samples can be tested to a specified minimum load or break, after which the crosshead automatically reverses to the home position in preparation for the next test. Wire harnesses can then be released for shipping, or re-crimped and re-tested as needed, without any scrap.

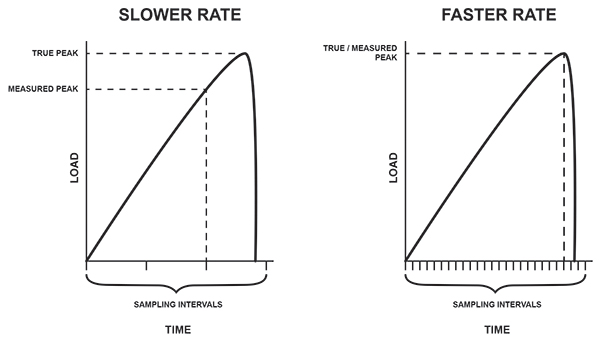

MESUR®gauge Plus software is used to initiate test stand motion and collect continuous or discrete data points, for reference and further analysis.

Gallery:

Products used:

- Model ESM1500LC motorized test stand

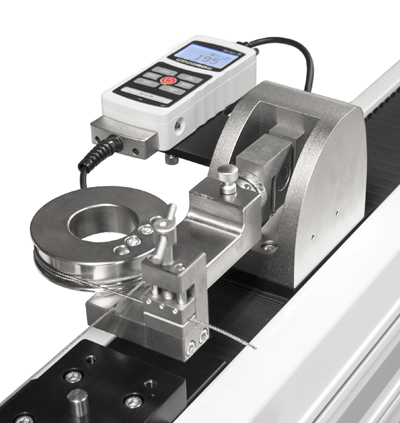

- Model M5i force/torque indicator

- MR01-2000-1 load cell, 2,000 lbF (10 kN) range

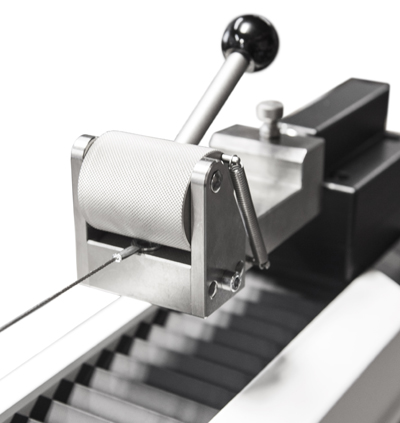

- G1092 wire/rope grip

- G1094 eccentric roller grip

- MESUR®gauge Plus software

- Custom modifications by our engineers and production staff

180° T-Peel Testing – ASTM F88 / D1876

180° T-Peel Testing – ASTM F88 / D1876 Keyswitch Actuation Force Measurement

Keyswitch Actuation Force Measurement Hand Sanitizer Packaging Analysis

Hand Sanitizer Packaging Analysis Measuring Mass in A Weightless Environment

Measuring Mass in A Weightless Environment Verifying Goggle Component Quality and Durability

Verifying Goggle Component Quality and Durability